Product Details

Features:

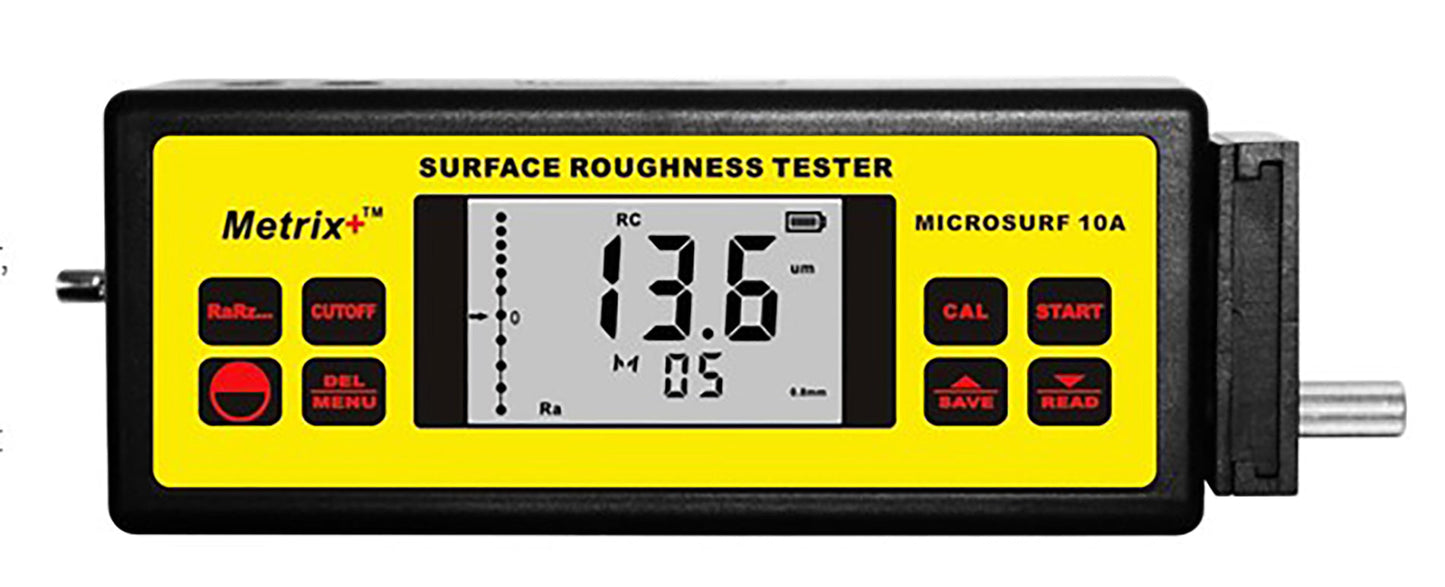

Multi-parameter measurement of Ra, Rq, Rz and Rt.

Backlit LCD display with indication for proper probe alignment.

Data storage and recall.

Metric/Imperial conversion.

Compact and low volume structure for convenient storage.

Applications:

Roughness is an important parameter when trying to find out whether a surface is suitable for a certain purpose. Rough surfaces often wear out more quickly than smoother surfaces. Rougher surfaces are normally more vulnerable to corrosion and cracks, but they can also aid in adhesion. A roughness tester is used to quickly and accurately determine the surface texture or surface roughness of a material. Few industries include automobile manufacturing and spare parts processing, machinery parts processing, metal processing equipment and accessories, surface engineering treatment, mold casting and precision manufacturing.

Measuring Principle:

This instrument has a sensor tip, using inductance type principle for measuring roughness. It is traversed over the sample, using a motor assembly, and its roughness will cause the sensor to be displaced. This displacement causes inductance of the sensor inductor to change and produces an analog signal proportional to the surface roughness.

- Choosing a selection results in a full page refresh.

- Opens in a new window.

Log in

Log in